Optimizing Operational Process Flow by up to 50%

novoElementum (nE) offers a proprietary designed in-house integrated system architecture has the potential to minimize operational inefficiencies across numerous sectors of industry with minimal investment from process owners. Commercial potential not only resides in savings alone but also in the potential to obviate other major costs associated with alternative approaches.

Optimization spans across pinpointing sub-optimal production assembly lines to reporting low inventory stock levels all in real-time. nE focuses on making your inventory flows fully transparent to company processes.

Offering a Uniquely Integrated Operational Optimization Solution

Our curated solution to industry incorporates proprietary designed cloud-connected physical sensors and in-house generated Artificial Intelligence (AI) derived predictions suited for the manufacturing and mining sectors. Our solution engages highly specialized embedded hardware, select sensors and a cloud environment to offer transparency of real-time material flow changes which are then tuned via operational intervention to correct process inefficiencies and operational bottlenecks.

We have integrated four modules which define the essence of our platform:

[A] Benchmarking Process Flow

[B] Locating Operational Bottlenecks

[C] Tracing Material Flow

[D] Monitoring Real-time Ground Data

A. Benchmarking Process Flow

We firstly establish the productivity throughput of your process calling on current and legacy data which to date may have been generated and established from in-place company CRM practices.

B. Locating Operational Bottlenecks

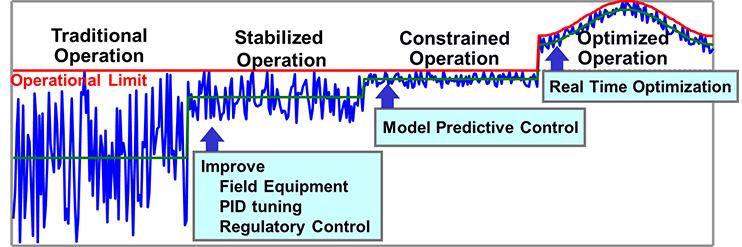

To locate operational bottlenecks, cutting edge machine learning methodologies are engaged to analyze preoptimized operational site data. Interpretations of plant efficiencies are assessed by experienced manufacturing, process, operations and mining professionals.

C. Tracing Material Flow

Flawless tracing of raw and manufactured product streams, in the form of finished discrete inventory items, is made possible by retrofitting our integrated proprietary sensor network design into an already established production environment. Such practice will ensure transparency and operating limits of production.